Cubitron™ II 051115-66534

Type 27 Depressed Center Cut-Off Wheel, 4-1/2" Dia x 1/8" THK, 5/8"-11 Threaded, 36 Grit, Precision Shaped Ceramic

- BIPN:

- MMM-51115-66534

- UPC:

- 51115665349

- Availability:

- Typically Ships in 1 to 7 Days

- Quantity Interval:

- 1 / EA - Each

Prop 65 - WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer and/or reproductive harm - www.P65Warnings.ca.gov

-

Cubitron™ II Depressed Center Wheel, 4-1/2 in Wheel Diameter, 1/8 in Wheel Thickness, Threaded Arbor Connector, 36 Grit, Very Coarse Grade, Precision Shaped Ceramic Abrasive, Wheel Type Number: Type 27, 13300 rpm Maximum, Resin Bond, Applicable Materials: All Metals, 5/8-11 Center Hole Thread Size, Wheel Hardness: S, Black Wheel, Yes Reinforced

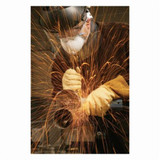

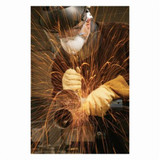

3M™ Cubitron™ II cut-off wheel features 3M™ precision shaped ceramic grain to bring you an exceptionally fast cutting and long-lasting wheel for use on almost all materials, including stainless steel, mild steel and aerospace alloys. This cut-off wheel surpasses 3M™ high performance wheels in both cut and life to deliver significant gains in productivity. Experience the power of 3M™ precision shaped grain to provide a cool, extra sharp, quick cut long after other wheels are consumed. Unlike coated abrasive discs, which shape or sand objects using the disc surface, cut-off wheels provide perpendicular cuts, using the outer edge of the wheel. Abrasive cut-off wheels are typically used for cutting through metal, for example autobody or marine sheet metal, stainless steel tubing, exhaust pipes, clamps and rusted fasteners. Cut-off wheels are attached to a cut-off wheel tool (sold separately) and must always be used with a wheel guard for safety. 3M™ Cubitron™ II products have raised the bar for high performing abrasives. 3M™ precision shaped grain (PSG) out cuts and outlasts conventional ceramic industrial abrasives and requires less grinding force to achieve superior performance. The result is that operators can grind faster and complete more parts per disc with less muscle work and fatigue. To create PSG, our engineers started with 3M™ ceramic abrasive grain and used proprietary technology to form the grains into triangular structures and electrostatically orient them on the backing to form sharp peaks that maximize cutting potential. These peaks slice cleanly through metal like a knife through butter, rather than gouging or plowing as traditional abrasives do and continuously self-sharpen as the points break off. This generates a super fast cut and lessens heat buildup due to friction, reducing heat-related stress cracks and discoloration. PSG also wears evenly and because the abrasive itself stays cooler and sharper, 3M™ Cubitron™ II products last significantly longer than their conventional ceramic counterparts, ensuring extended high performance in production applications.

-

- Type Performance - Depressed Center

- Series Cubitron II

- Wheel Diameter 4-1/2 in

- Wheel Thickness 1/8 in

- Center Hole Thread Size 5/8-11

- Grit 36

- Grade Very Coarse

- Abrasive Material Precision Shaped Ceramic

- Maximum Speed 13300 rpm

- Applicable Materials All Metals

- Wheel Type Number Type 27

-

- Triangular shaped ceramic grain wears evenly, runs cool and optimizes mineral breakdown for extra long life

- Cool cutting for a higher quality and faster cut

- Must be used with a wheel guard that fits the size of the cut-off wheel

- Quick-change attachment for improved productivity and throughput